Design

Each product is distinguished by a unique set of attributes—from its recipe and history to its origin, the company behind it, and the values it aims to convey. It is for this reason that Huayuan supports its clients from the very start of the delicate process of developing a bespoke glass container, ensuring the distinctive qualities of the content are in perfect harmony with those of the final packaging.

Sometimes a client comes with a simple sketch of an envisioned shape; other times, they seek to personalize an existing product. There are also instances where Huayuan proactively proposes an entirely new concept, inspired by the client’s ideas and expectations.

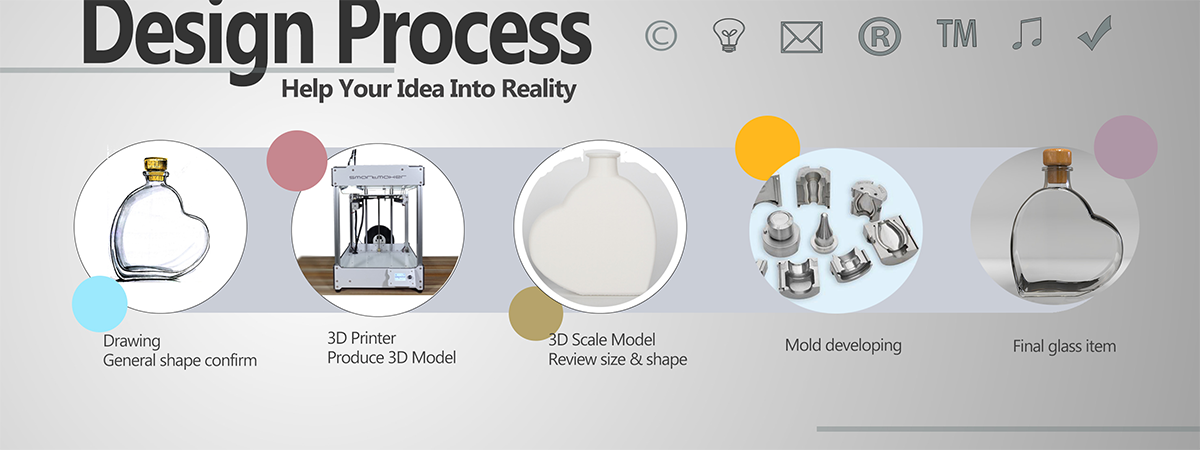

Our Design Department offers comprehensive support throughout the design of each unique glass container—from initial hand-drawn sketches to detailed 3D models that allow clients to evaluate designs long before physical samples are produced. This turns design into a strategic advantage, not merely a matter of style.

The Five Steps to Production

1 Defining the brief

Our design team then further explores these requirements, developing concepts that not only align with your initial brief but also propose potential enhancements to optimize the container for both production and filling processes.

2. Initial concept

Bringing the concept to life is crucial. We present this through the format that best suits your needs—be it an outline drawing, a 3D visualization, or a physical mock-up.

A photorealistic 3D visualization is most common, offering a clear view of the finished product, complete with labels and closures if applicable. For a tangible assessment, we can also provide precise models crafted from acrylic, wood, or glass.

Once the design is finalized to your satisfaction, we create a comprehensive technical specification drawing for your formal sign-off. This design is reviewed and approved by key departments throughout our organization to ensure feasibility and quality.

3. Designing the mould equipment

4.Sampling the container

After a rigorous inspection by our quality department, these samples are sent to you for real-world testing on your filling lines. You can assess label application, and compatibility with closures and secondary packaging before granting formal approval for bulk production.

5.Full scale production

Upon receipt of the final mould equipment and your manufacturing authorization, we commence full-scale production. Every container undergoes a stringent final inspection by our advanced equipment before being carefully packed and delivered directly to you.